HOME 技術資料室 技術用語

=========================================

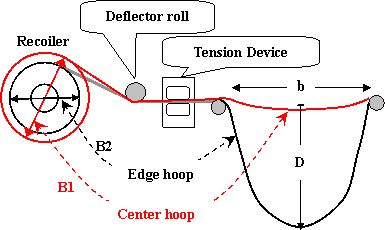

At the end of slitter line, the slit strips are wound up by recoiler,

where the edge strips are wound up into smaller diameter than the center

strip, because edge strips are thinner than the center one. However all

these slit strips are wound by the same single reel, edge strips are wound

up slowly compared to the center strips resulting slackened edge strips.

At the end of slitter line, the slit strips are wound up by recoiler,

where the edge strips are wound up into smaller diameter than the center

strip, because edge strips are thinner than the center one. However all

these slit strips are wound by the same single reel, edge strips are wound

up slowly compared to the center strips resulting slackened edge strips.The purpose of the delivery looping pit is to absorb the difference of the speed for each strips i.e. the slackened edge strips.

Difference of tail end length between center and edge strips after coil of W ton recoiled

| Case-1 | Case-2 | Case-3 | Case-4 | Case-5 | Case-6 | ||

| Coil weight | W ton | 18 | 18 | 18 | 18 | 18 | 18 |

| Center hoop thickness | tc mm | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Strip width | A mm | 1,650 | 1,650 | 1,650 | 1,200 | 1,200 | 1,200 |

| Total length | L1 m | 2,779 | 2,779 | 2,779 | 3,822 | 3,822 | 3,822 |

| Thickness deviation at strip edge | −μ | −4 | −6 | −8 | −4 | −6 | −8 |

| Outer diameter of center hoop | B1 mm | 1,424 | 1,424 | 1,424 | 1,641 | 1,641 | 1,641 |

| Number of layers | T | 916 | 916 | 916 | 1,133 | 1,133 | 1,133 |

| Outer diameter of edge hoop | B2 mm | 1,417 | 1,413 | 1,410 | 1,632 | 1,627 | 1,623 |

| Length of edge hoop at T | L2 m | 2,769 | 2,764 | 2,758 | 3,806 | 3,797 | 3,789 |

| Required loop length | L1-L2 m | 10.5 | 15.8 | 21.1 | 16.1 | 24.2 | 32.2 |

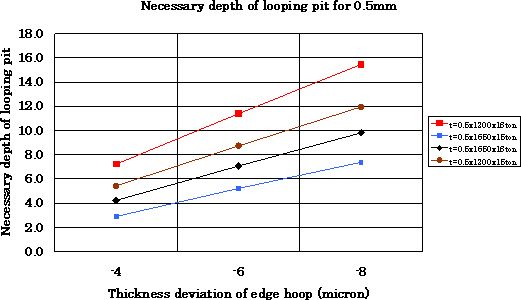

Necessary looping pit size / calculation of catenary D=y(b/2)-y(0)=a cosh(b/(2a)) -a

| Case-1 | Case-2 | Case-3 | Case-4 | Case-5 | Case-6 | ||

| Width of catenary | b mm | 5,080 | 5,080 | 5,080 | 5,080 | 5,080 | 5,080 |

| Catenary shape constant | a | 1.14 | 0.88 | 0.77 | 0.87 | 0.72 | 0.65 |

| Calculated length of catenary | Lc m | 10.5 | 15.8 | 21.1 | 16.1 | 24.2 | 32.2 |

| Depth of catenary from passline | D m | 4.2 | 7.1 | 9.8 | 7.2 | 11.4 | 15.5 |

=======================================

HOME 技術資料室 スリッターライン