What is gFive Sh

@gFive Sh is the name of the workplace campaign that consists of five activities, all start with the letter S in Japanese. When translate or transliterate into English, we should not stick to the letter S to keep the basic idea accurately.

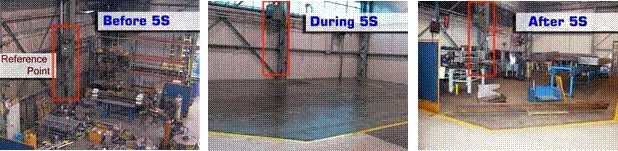

2.Aim of gFive Sh Campaign

@The aim of gFive Sh Campaign is to change the workplace from disordered state to well-ordered one through five simple and visible activities. By promoting this campaign, not only the work area but the mind and behavior of the working people become well-ordered and positive. When the working people have pride in their work and workplace it can lead to greater job satisfaction and higher productivity.

@The effect of gFive Sh has been proved in many workplaces in the world.

3. Activities of gFive ShCampaign

@gFive Sh Campaign consists of the following five simple and visible activities;

1) Sorting

@Keep only what is necessary in work area and in order. Eliminate or discard items that are not used frequently, leaving only the tools and materials necessary to perform daily activities. Donft keep things around just because they might be used someday, which make easier to find the necessary things for the job done and frees up additional space.

2) Setting in order

@Organize, arrange and identify everything in a work area. Each tool, part, supply, piece of equipment, everything should be placed in the decided place which should be close to where it is used.

@Outline areas on the floor to identify work areas, movement lanes, storage areas, finished product areas, etc.

@Put shadows on tool boards and labels to cabinets or shelves making it

easy to quickly see where each tool or thing belongs.

@Put shadows on tool boards and labels to cabinets or shelves making it

easy to quickly see where each tool or thing belongs.3) Regular cleaning

@Keep the work area tidy and organized. At the end of each shift or operation, work area shall be cleaned, checking that everything is stored to its place.

@A key point that cleaning operation should be part of the daily work, not an occasional activity initiated when work area get messy. Donft allow litter, scrap, rag, paper etc., to land on the floor in the first place.

4) Standardization

@To ensure that the first three steps continue to be effective, it is necessary to make these three activities into work standard at the workplace and develop a work structure that will support the new practices and make them into habit.

@Everyone should know exactly what his or her responsibilities are for adhering to the first three activities.

@Work standard should be always reviewed to a better way.

5) Sustaining the descipline

@Maintain focus on this new way and do not allow a gradual decline back to the old way, having a formal system for monitoring the results of these activities.

@Make these activities to the discipline and habit of each working individual to maintain this new way.

@When improvement is suggeted, such as better way of working or new tool, the first four activities should be reviewed and modified.

HOME@ZpΏΊ